In traditional construction, one of the most common techniques for waterproofing walls for projects like a tile installation, is to use waterproof coatings or hydrophobic mortars with waterproof cement. In this post, we will explore what waterproof mortar is, how to mix it, and some application tips.

What is Waterproof Cement?

Waterproof mortar is a type of cement that prevents water from penetrating, starting from the moment of construction, and prevents the appearance of dampness. This helps to prevent the paint on our walls and ceilings from peeling. It allows us to build and waterproof simultaneously.

It can be used for all types of construction, especially those exposed to the elements and moisture, as it protects walls, foundations, and roofs. When plastering an exterior wall, it is applied directly onto the brick. This creates a protective barrier that prevents moisture from seeping into the walls of the house.

Waterproof mortar is specially formulated for waterproofing walls. However, if we don’t mix it correctly or follow certain application guidelines, we won’t achieve its maximum performance, and the results might not meet expectations. While everyone in construction knows what waterproof cement is, not everyone knows how to mix it or apply it correctly. Let’s cover the essentials.

How to Mix Waterproof Cement

One of the first mistakes when trying to waterproof walls is the incorrect use of proportions in the preparation of the waterproofing mix. The sand-to-cement ratio is 4 to 1. When we say 1 part cement to 4 parts sand, we are referring to volumes (buckets, containers, etc.) and not to weights.

A hydrophobic agent is a waterproofing additive for cement, which, when added to water, helps to seal the pores of the cement mortar, enhancing its moisture resistance. This is one of the simplest ways to prevent dampness in walls.

For the hydrophobic or waterproofing agent, there is also a basic proportion that must be respected when mixing it with water: 1 part waterproofing agent to 10 parts water. If this proportion (1:10) is not followed, we might encounter moisture problems in the walls in the future.

The prepared water mixture is used to hydrate the sand and cement mixture (1:4). We mix it all with an electric mixer for greater homogeneity, speed, and convenience. At RUBI, we have one of the most comprehensive ranges with our RUBIMIX products. We invite you to check them out on our website.

Application Tips

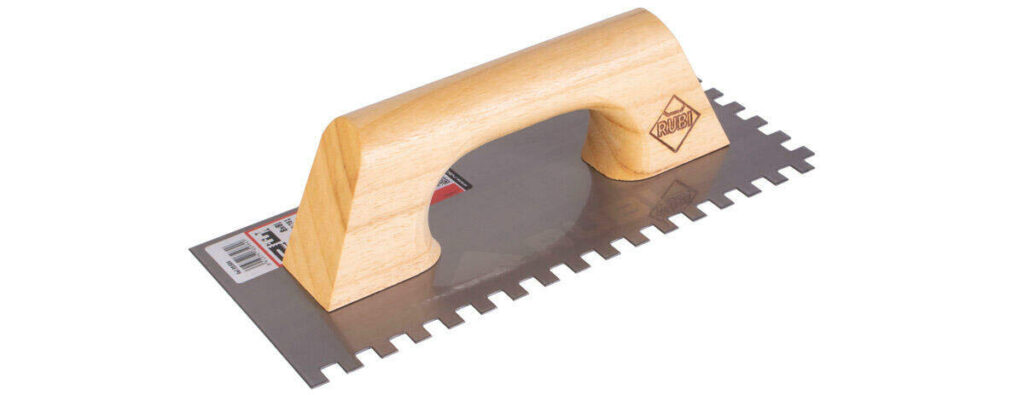

When applying waterproof cement with a trowel, the layer should be at least 5 to 8mm thick. A common mistake when spreading the waterproof mortar is pressing too hard, which reduces its thickness, thereby diminishing its waterproofing capability. Therefore, we must ensure that we maintain these minimum thicknesses if we want to avoid future moisture problems.

To apply waterproof cement on a wall to insulate it from moisture, people often make the mistake of not adequately wetting the walls before plastering. When the sand and cement mixture (1:4) is hydrated, water is the key element that promotes the setting. Setting is the chemical reaction that occurs to harden the mortar or cement and provide it with adequate waterproofing properties.

The water in the hydrophobic mixture must remain present for an extended period during the setting process. If it evaporates too soon, the mixture “burns out,” meaning it loses its waterproofing ability.

Hydrating the Walls

If the wall or surface where we are applying the waterproof cement is made of bricks and they are not properly moistened before plastering, they act like “sponges,” absorbing the water from the waterproof mixture. This disrupts the chemical reaction that hardens the mortar. Sustained water presence is essential to initiate the chemical reaction that causes the mortar to set (harden). If they dry too early, they lose their effectiveness as moisture barriers.

This means that if the wall in question is not properly moistened in terms of both time and amount of water (using a bucket or can is not sufficient), the waterproof cement plaster will not reach its maximum performance. Then, we’ll need to find solutions to eliminate moisture from the walls once it has already become a reality.

If the waterproof mortar (plaster) is not immediately covered with the next layer of coarse plaster (no more than 1/2 hour later), there is a risk that it will dry out due to wind or direct sunlight. Hence, it is so important not only to cover it with another layer of cement mortar but also to protect this coarse plaster with good “curing.”

“Curing” involves keeping the freshly plastered walls hydrated. They should be moistened three times a day for at least 3 to 4 days.

Good “curing” will prevent the coarse plaster from cracking as it dries (shrinkage cracks) and will stop these cracks from becoming pathways for moisture from the outside.

Now that you know more about what waterproof cement is, how to mix it, and some tips for applying it, you can confidently venture into using it.

Post a comment